Installation Guides

importaNT Notice

If your vehicle was originally equipped with a CVTech-IBC product, the information provided by the manufacturer regarding the maintenance of our products installed at their factories (OEM) will always take precedence over the information found on our website.

Only qualified personnel should perform maintenance and repair operations on this continuously variable pulley.

ⓘ

Means there is a risk of serious injuries if the instructions are not followed as described.

✋

Means that, when performing this step, there is a risk of damaging a part or may cause components malfunction.

Limitation of liability

CVTech-IBC shall not be liable for any damage or injury resulting from misunderstanding of the text, improper use of the transmission system, or improper use of the recommended tools.

It is very important to always use the indicated tightening torque.

Maintenance Frequency

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations :

‐ Perform maintenance specific to your pulley according to the recommendations of your vehicle’s manufacturer or, if applicable, according to the correct table in the section below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

Technical Documentation

Driver Pulley

0400-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 0400-XXXX

Installation Manual PDF (En)

How to adjust your powerbloc clutch (EN)

specific instructions – 0400-0387 for ARGO vehicles since 2022 (bilingual)

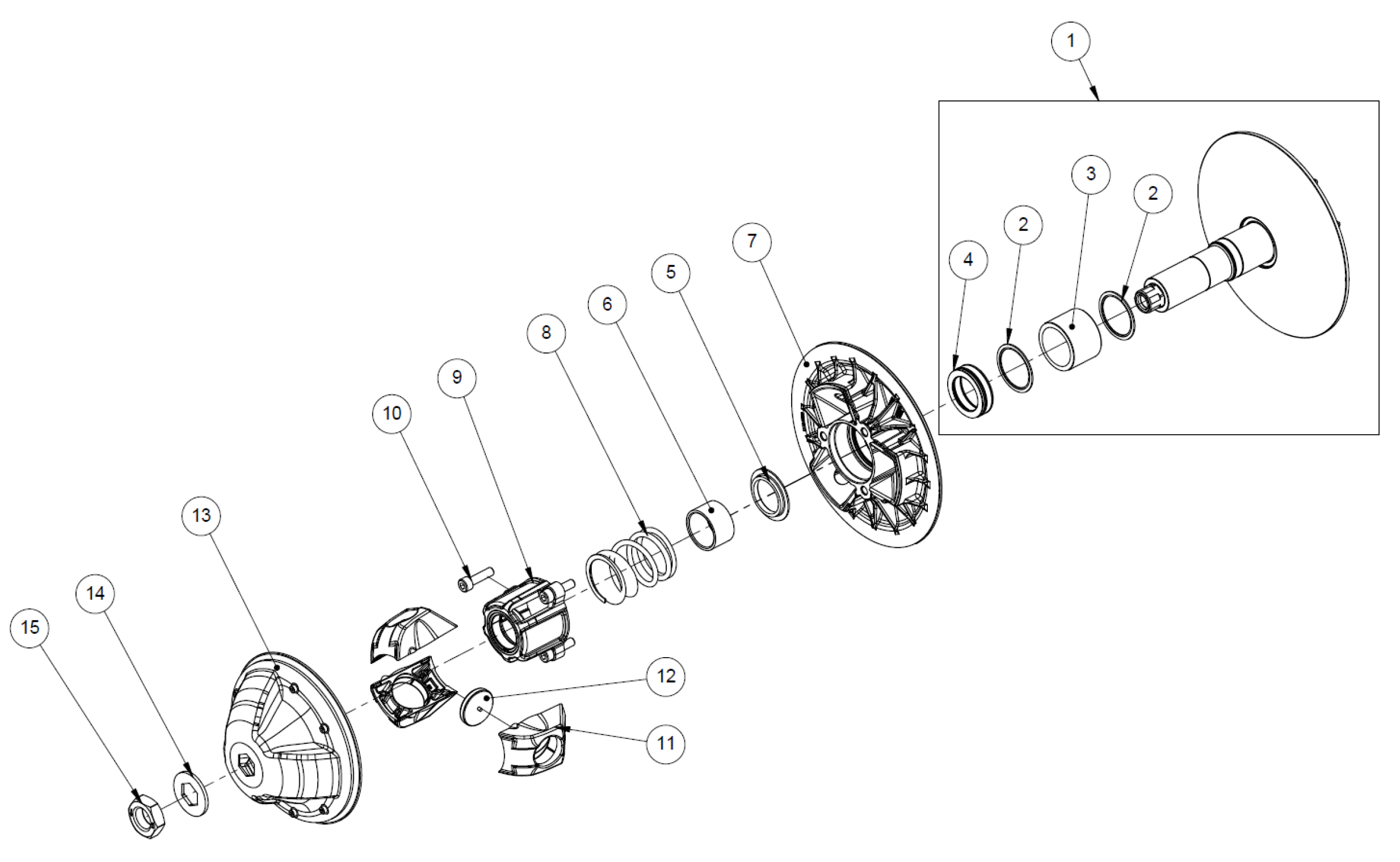

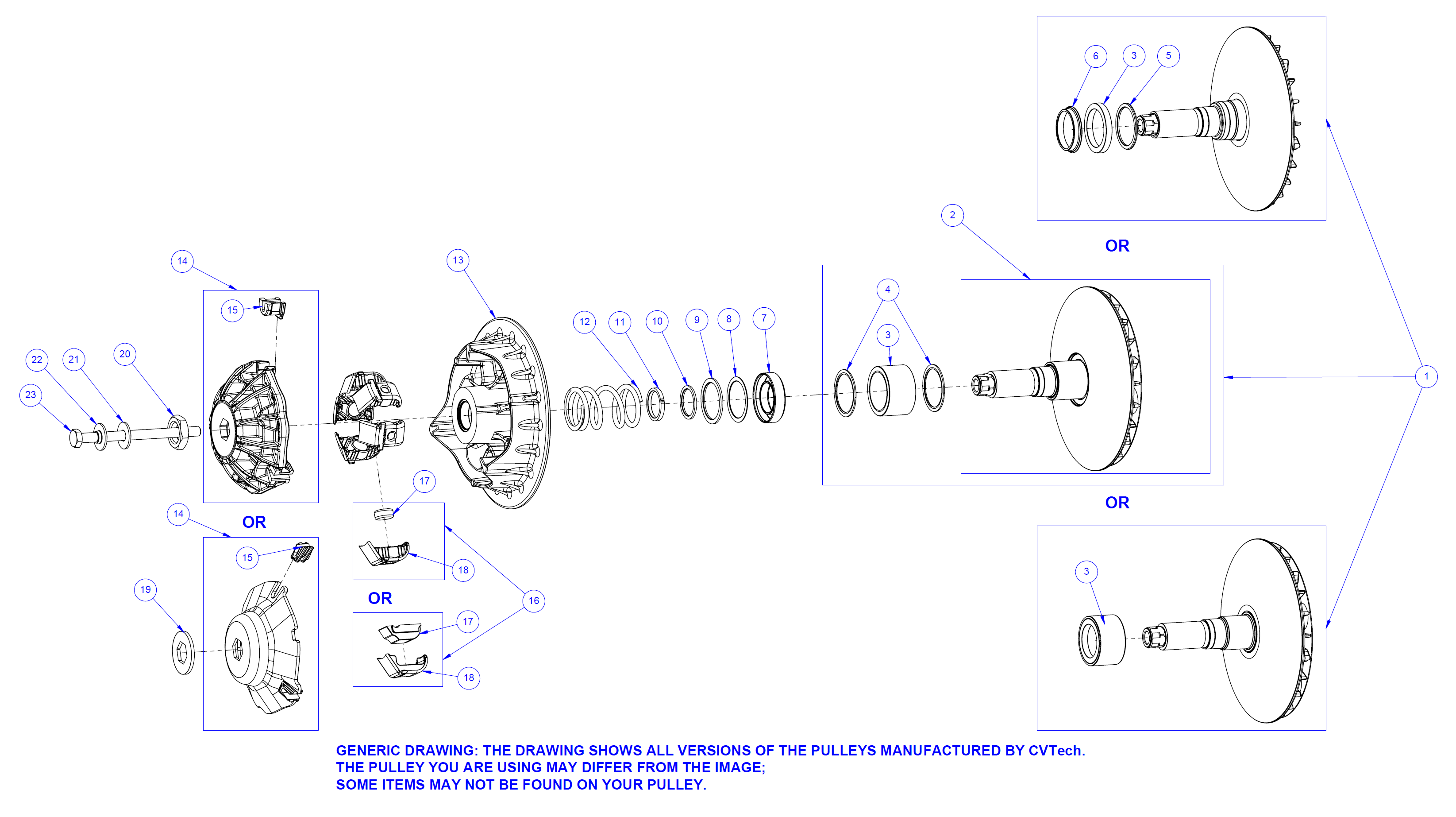

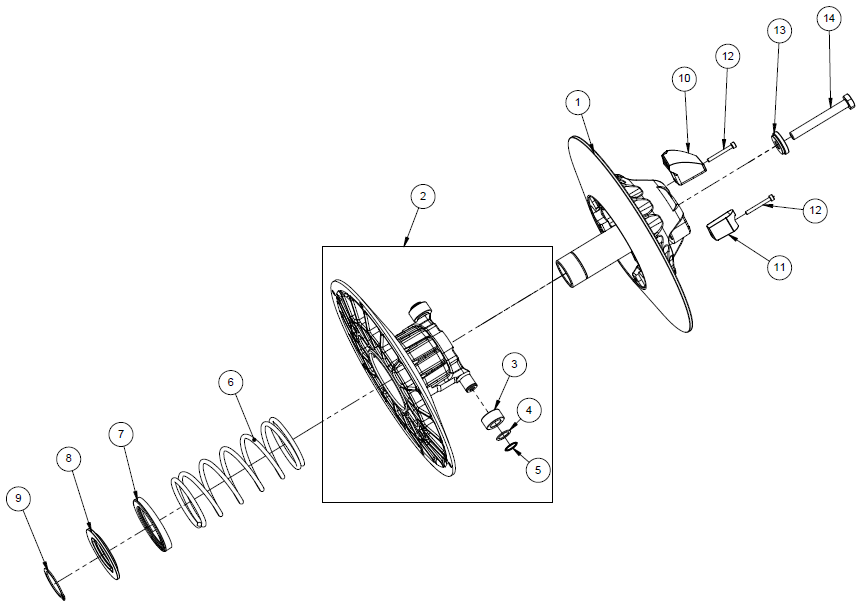

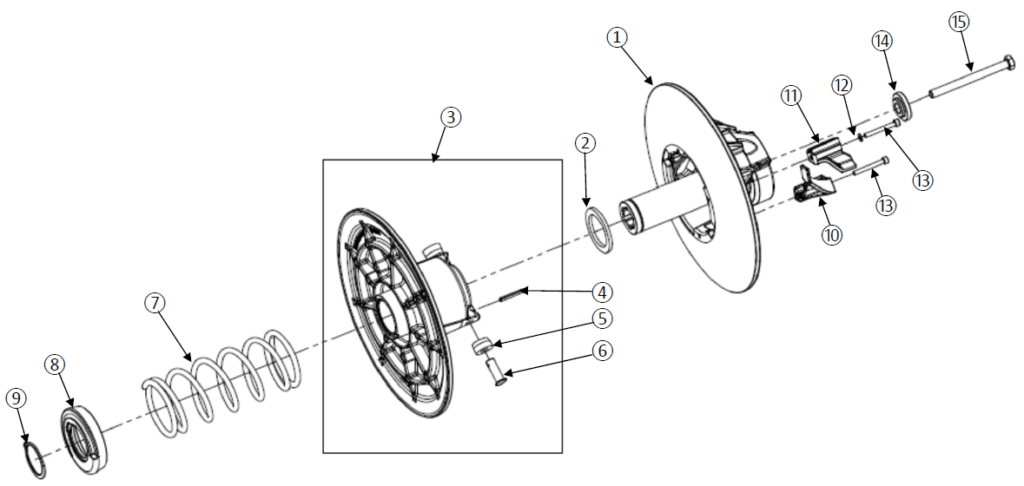

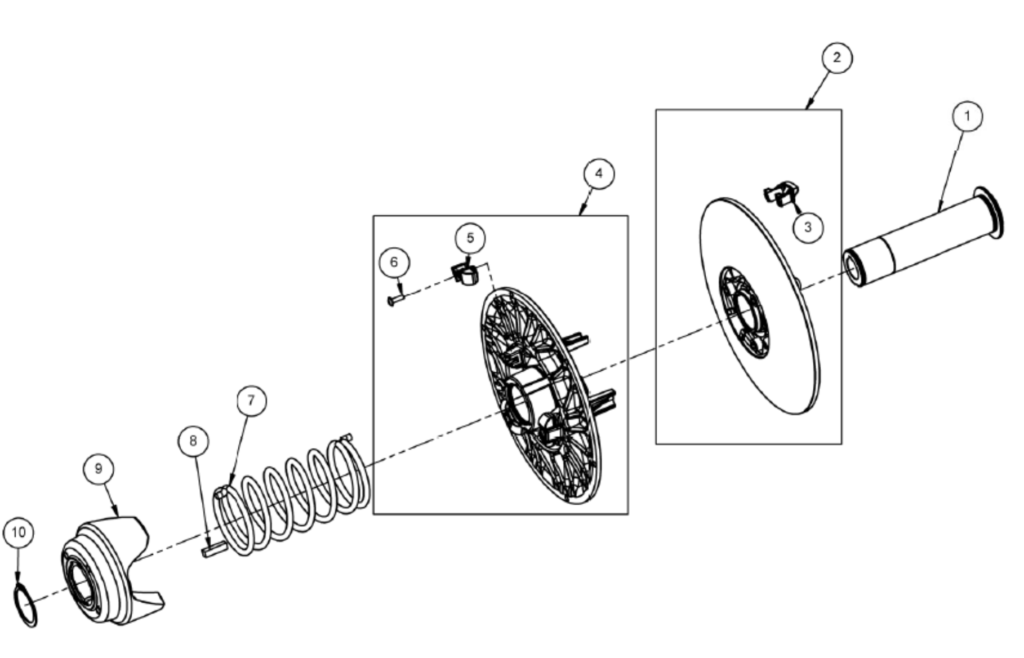

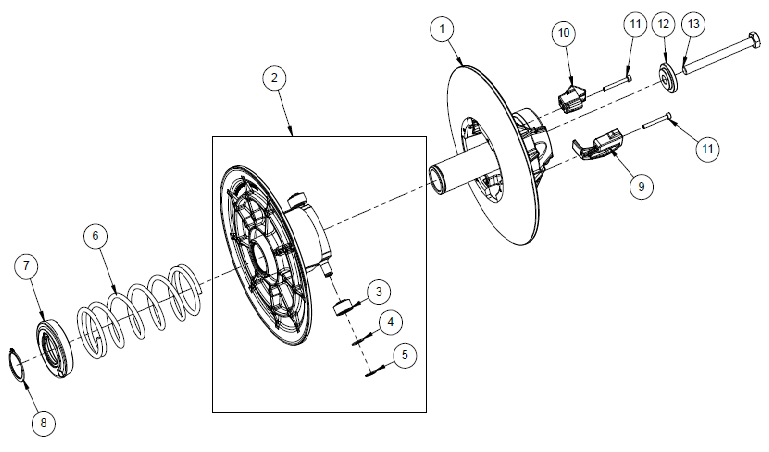

DRIVE PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | fixed sheave | 1 |

| 2 | sliding sheave | 1 |

| 3 | Spring support | 1 |

| 4 | Spring | 1 |

| 5 | Stroke limiter | 1 or 0 |

| 6 | Spring cover | 1 |

| 7 | Lock washer | 3 |

| 8 | Hexagon S.H.C.S | 3 |

| 9 | Block | 3 |

| 10 | Weight | calibration Specific |

| # | Description | QTY |

|---|---|---|

| 11 | Weight | calibration Specific |

| 12 | Threaded cap | calibration Specific |

| 13 | Assembly block | 3 |

| 14 | Cap | 1 |

| 15 | Flat washer | 1 OR 0 |

| 16 | nut | 1 |

| 17 | Lock washer | 1 |

| 18 | Fixing bolt | 1 OR 0 |

| 19 | Puller | n/a |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

| # PULLEY | 6mm HEXAGON S.H.C.S. (PART #8)1 N∙m | 6mm HEXAGON S.H.C.S. (PART #8)1 Lbf∙in | NUT (PART #16)1 N∙m | NUT (PART #16)1 Lbf∙ft |

|---|---|---|---|---|

| 0400-0170 | 10 | 89 | 125 | 92 |

| 0400-0170 | 10 | 89 | 125 | 92 |

| 0400-0171 | 10 | 89 | 125 | 92 |

| 0400-0172 | 10 | 89 | 125 | 92 |

| 0400-0173 | 10 | 89 | 125 | 92 |

| 0400-0174 | 10 | 89 | 125 | 92 |

| 0400-0175 | 10 | 89 | 125 | 92 |

| 0400-0176 | 10 | 89 | 125 | 92 |

| 0400-0177 | 10 | 89 | 125 | 92 |

| 0400-0178 | 10 | 89 | 125 | 92 |

| 0400-0179 | 10 | 89 | 125 | 92 |

| 0400-0180 | 10 | 89 | 125 | 92 |

| 0400-0181 | 10 | 89 | 125 | 92 |

| 0400-0182 | 10 | 89 | 125 | 92 |

| 0400-0183 | 10 | 89 | 125 | 92 |

| 0400-0184 | 10 | 89 | 125 | 92 |

| 0400-0185 | 10 | 89 | 125 | 92 |

| 0400-0186 | 10 | 89 | 125 | 92 |

| 0400-0187 | 10 | 89 | 125 | 92 |

| 0400-0188 | 10 | 89 | 125 | 92 |

| 0400-0189 | 10 | 89 | 125 | 92 |

| 0400-0190 | 10 | 89 | 125 | 92 |

| 0400-0191 | 10 | 89 | 125 | 92 |

| 0400-0192 | 10 | 89 | 125 | 92 |

| 0400-0193 | 10 | 89 | 125 | 92 |

| 0400-0194 | 10 | 89 | 125 | 92 |

| 0400-0195 | 10 | 89 | 125 | 92 |

| 0400-0196 | 10 | 89 | 125 | 92 |

| 0400-0197 | 10 | 89 | 125 | 92 |

| 0400-0198 | 10 | 89 | 125 | 92 |

| 0400-0199 | 10 | 89 | 125 | 92 |

| 0400-0200 | 10 | 89 | 125 | 92 |

| 0400-0201 | 10 | 89 | 125 | 92 |

| 0400-0202 | 10 | 89 | 125 | 92 |

| 0400-0203 | 10 | 89 | 125 | 92 |

| 0400-0204 | 10 | 89 | 125 | 92 |

| 0400-0205 | 10 | 89 | 125 | 92 |

| 0400-0206 | 10 | 89 | 125 | 92 |

| 0400-0210 | 10 | 89 | 125 | 92 |

| 0400-0211 | 10 | 89 | 125 | 92 |

| 0400-0212 | 10 | 89 | 125 | 92 |

| 0400-0213 | 10 | 89 | 125 | 92 |

| 0400-0214 | 10 | 89 | 125 | 92 |

| # PULLEY | 6mm HEXAGON S.H.C.S. (PART #8)1 N∙m | 6mm HEXAGON S.H.C.S. (PART #8)1 Lbf∙in | NUT (PART #16)1 N∙m | NUT (PART #16)1 Lbf∙ft |

|---|---|---|---|---|

| 0400-0215 | 10 | 89 | 125 | 92 |

| 0400-0216 | 10 | 89 | 125 | 92 |

| 0400-0217 | 10 | 89 | 125 | 92 |

| 0400-0218 | 10 | 89 | 125 | 92 |

| 0400-0219 | 10 | 89 | 125 | 92 |

| 0400-0220 | 10 | 89 | 125 | 92 |

| 0400-0221 | 10 | 89 | 125 | 92 |

| 0400-0222 | 10 | 89 | 125 | 92 |

| 0400-0223 | 10 | 89 | 125 | 92 |

| 0400-0224 | 10 | 89 | 125 | 92 |

| 0400-0225 | 10 | 89 | 125 | 92 |

| 0400-0226 | 10 | 89 | 125 | 92 |

| 0400-0227 | 10 | 89 | 125 | 92 |

| 0400-0228 | 10 | 89 | 125 | 92 |

| 0400-0229 | 10 | 89 | 125 | 92 |

| 0400-0242 | 10 | 89 | 125 | 92 |

| 0400-0244 | 10 | 89 | 125 | 92 |

| 0400-0245 | 10 | 89 | 125 | 92 |

| 0400-0246 | 10 | 89 | 125 | 92 |

| 0400-0247 | 10 | 89 | 125 | 92 |

| 0400-0248 | 10 | 89 | 125 | 92 |

| 0400-0249 | 10 | 89 | 125 | 92 |

| 0400-0253 | 10 | 89 | 125 | 92 |

| 0400-0254 | 10 | 89 | 125 | 92 |

| 0400-0285 | 10 | 89 | 125 | 92 |

| 0400-0287 | 10 | 89 | 125 | 92 |

| 0400-0303 | 10 | 89 | 125 | 92 |

| 0400-0304 | 10 | 89 | 125 | 92 |

| 0400-0305 | 10 | 89 | 125 | 92 |

| 0400-0306 | 10 | 89 | 125 | 92 |

| 0400-0307 | 10 | 89 | 125 | 92 |

| 0400-0308 | 10 | 89 | 125 | 92 |

| 0400-0309 | 10 | 89 | 125 | 92 |

| 0400-0310 | 10 | 89 | 125 | 92 |

| 0400-0312 | 10 | 89 | 125 | 92 |

| 0400-0313 | 10 | 89 | 125 | 92 |

| 0400-0314 | 10 | 89 | 125 | 92 |

| 0400-0315 | 10 | 89 | 125 | 92 |

| 0400-0316 | 10 | 89 | 125 | 92 |

| 0400-0317 | 10 | 89 | 125 | 92 |

| 0400-0329 | 10 | 89 | 125 | 92 |

| 0400-0330 | 10 | 89 | 125 | 92 |

| 0400-0359 | 10 | 89 | 125 | 92 |

| 0400-0370 | 10 | 89 | 125 | 92 |

1 : See « Drive Pulley Disassembly » to correctly identify the referenced part.

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

web version coming soon. Please refer to the installation Manual.

0500-xxxx (Guides coming soon)

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 0500-XXXX

Download the full PDF version (coming soon)

DRIVE PULLEY DISASSEMBLY

Coming Soon

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

Coming soon

NECESSARY SPECIALIZED TOOLS

Coming Soon

0600-xxxx (Guides coming soon)

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 0600-XXXX

Download the full PDF version (coming soon)

DRIVE PULLEY DISASSEMBLY

Coming soon

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

Coming soon

NECESSARY SPECIALIZED TOOLS

Coming Soon

0900-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 0900-XXXX

Download the full PDF version (En)

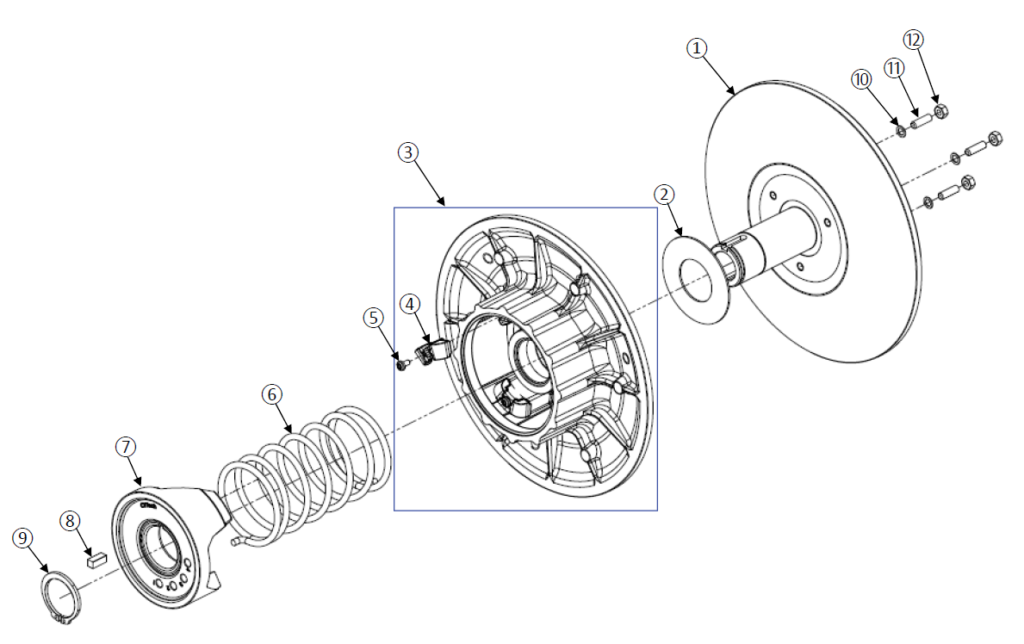

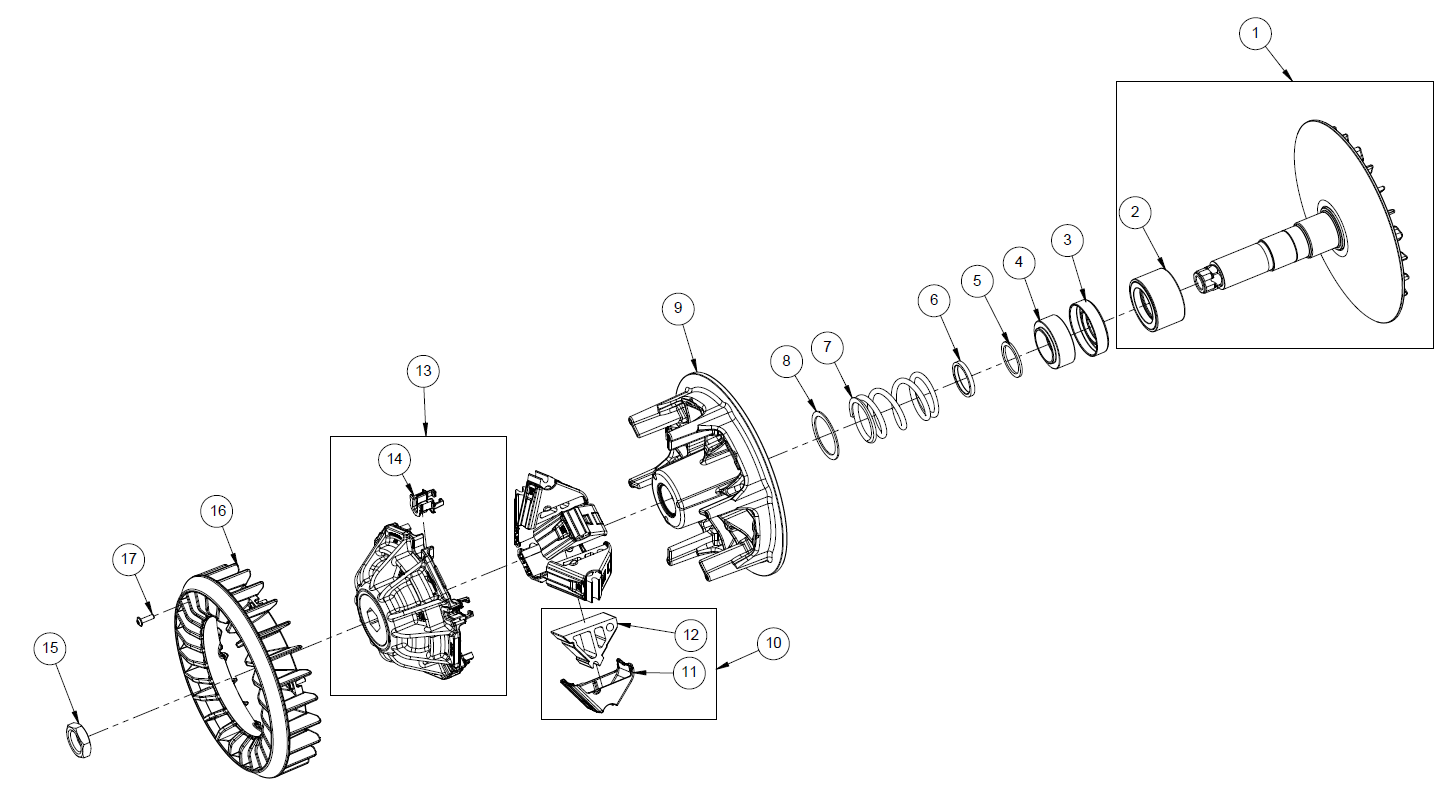

DRIVE PULLEY DISASSEMBLY

| # | Description | Qty |

|---|---|---|

| 1 | Fixed sheave | 1 |

| 2 | Fixed sheave without bearing nor shims (if applicable) | 1 |

| 3 | Freewheel or idle bearing | 1 |

| 4 | Shims | 2 or 0 |

| 5 | Shim | 1 or 0 |

| 6 | Spacer | 1 or 0 |

| 7 | Spring seat | 1 |

| 8 | Shim (if applicable) | 1 |

| 9 | Shim (if applicable) | 1 |

| 10 | Shim | 1 |

| 11 | Stroke limiter | 1 |

| 12 | Spring | 1 |

| # | Description | Qty |

|---|---|---|

| 13 | Sliding sheave | 1 |

| 14 | Cap | 1 |

| 15 | Cap shoe | 3 |

| 16 | Centrifugal Mass | 6 |

| 17 | Mass | 6 |

| 18 | Block | 6 |

| 19 | Washer | 1 or 0 |

| 20 | Nut | 1 or 0 |

| 21 | Washer (if applicable) | 1 or 0 |

| 22 | Washer (if applicable) | 1 or 0 |

| 23 | Fixing Screw (if applicable) | 1 or 0 |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

| # PULLEY | NUT (PART #17)1 N∙m | NUT (PART #17)1 Lbf∙in |

|---|---|---|

| 0900-0281 | 200 | 148 |

| 0900-0288 | 200 | 148 |

| 0900-0289 | 200 | 148 |

| 0900-0290 | 200 | 148 |

| 0900-0291 | 200 | 148 |

| 0900-0292 | 200 | 148 |

| 0900-0293 | 200 | 148 |

| 0900-0294 | 200 | 148 |

| 0900-0295 | 200 | 148 |

| 0900-0296 | 200 | 148 |

| 0900-0299 | 200 | 148 |

| 0900-0300 | 200 | 148 |

| 0900-0301 | 200 | 148 |

| 0900-0324 | 150 | 111 |

| 0900-0325 | 150 | 111 |

| 0900-0378 | 150 | 111 |

| 0900-0379 | 150 | 111 |

| 0900-0380 | 150 | 111 |

| 0900-0381 | 150 | 111 |

| 0900-0382 | 150 | 111 |

| 0900-0383 | 150 | 111 |

| 0900-0384 | 150 | 111 |

| 0900-0385 | 150 | 111 |

| 0900-0386 | 150 | 111 |

| 0900-0387 | 150 | 111 |

| 0900-0388 | 150 | 111 |

| 0900-0389 | 150 | 111 |

| 0900-0390 | 150 | 111 |

| # PULLEY | NUT (PART #17)1 N∙m | NUT (PART #17)1 Lbf∙in |

|---|---|---|

| 0900-0391 | 150 | 111 |

| 0900-0393 | 150 | 111 |

| 0900-0394 | 150 | 111 |

| 0900-0395 | 150 | 111 |

| 0900-0396 | 150 | 111 |

| 0900-0397 | 150 | 111 |

| 0900-0398 | 150 | 111 |

| 0900-0399 | 150 | 111 |

| 0900-0400 | 150 | 111 |

| 0900-0401 | 150 | 111 |

| 0900-0402 | 150 | 111 |

| 0900-0403 | 150 | 111 |

| 0900-0404 | 150 | 111 |

| 0900-0405 | 150 | 111 |

| 0900-0406 | 150 | 111 |

| 0900-0408 | 150 | 111 |

| 0900-0409 | 150 | 111 |

| 0900-0410 | 150 | 111 |

| 0900-0411 | 150 | 111 |

| 0900-0423 | 200 | 148 |

| 0900-0424 | 200 | 148 |

| 0900-0425 | 150 | 111 |

| 0900-0426 | 150 | 111 |

| 0900-0429 | 150 | 111 |

| 0900-0433 | N/A | N/A |

| 0900-0473 | 200 | 148 |

| 0900-0522 | 200 | 148 |

| 0900-0523 | 200 | 148 |

1 : See « Drive Pulley Disassembly » to correctly identify the referenced part.

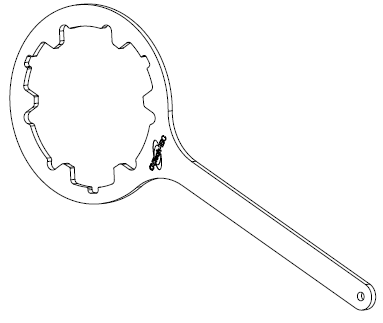

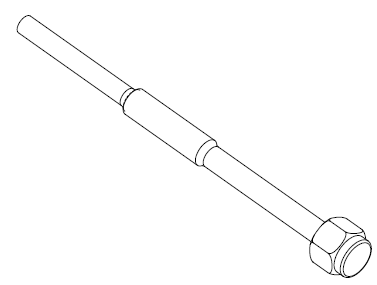

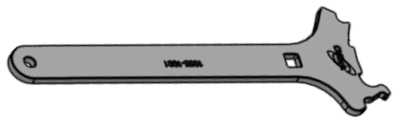

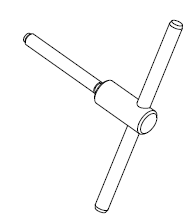

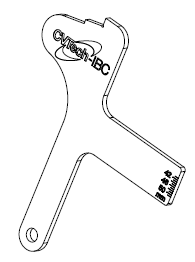

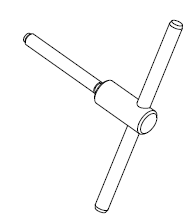

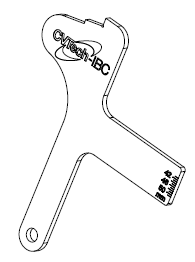

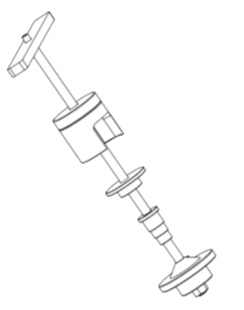

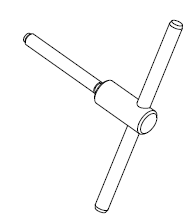

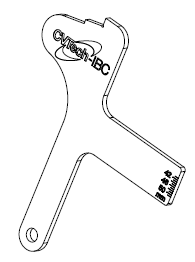

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

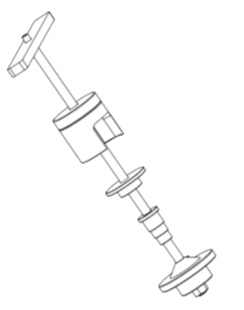

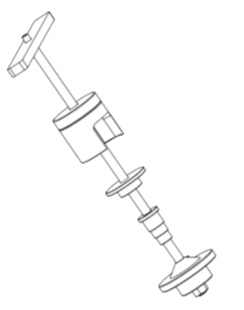

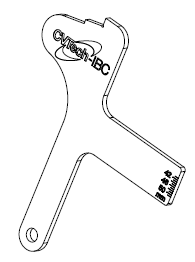

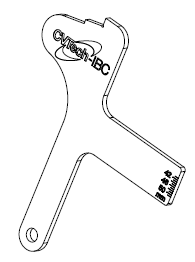

Description

Image

CVTech-IBC NUMBER

Retaining Tool

0155-1018*

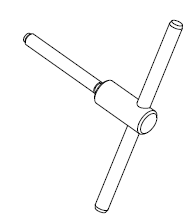

Puller

Refer to owner’s manual for part number*

* Tools available from authorized CVTech-IBC distributors

1100-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 1100-XXXX

Installation Manual (en)

How to adjust your Powerbloc 80 clutch (EN)

DRIVE PULLEY DISASSEMBLY

web version coming soon. Please refer to the installation Manual.

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

| # PULLEY | 6mm SCREW (PART #8)1 N∙m | 6mm SCREW (PART #8)1 Lbf∙po | NUT (PART #16)1 N∙m | NUT (PART #16)1 Lbf∙ft |

|---|---|---|---|---|

| 1100-0202 | 25 | 18 | 140 | 103 |

| 1100-0203 | 25 | 18 | 140 | 103 |

| 1100-0204 | 25 | 18 | 140 | 103 |

| 1100-0205 | 25 | 18 | 140 | 103 |

| 1100-0206 | 25 | 18 | 140 | 103 |

| 1100-0207 | 25 | 18 | 140 | 103 |

| 1100-0208 | 25 | 18 | 140 | 103 |

| 1100-0209 | 25 | 18 | 140 | 103 |

| 1100-0210 | 25 | 18 | 140 | 103 |

| 1100-0212 | 25 | 18 | 140 | 103 |

| 1100-0217 | 25 | 18 | 140 | 103 |

| 1100-0222 | 25 | 18 | 140 | 103 |

| 1100-0223 | 25 | 18 | 140 | 103 |

| 1100-0224 | 25 | 18 | 140 | 103 |

| 1100-0225 | 25 | 18 | 140 | 103 |

| 1100-0228 | 25 | 18 | 140 | 103 |

| 1100-0241 | 25 | 18 | 140 | 103 |

| 1100-0244 | 25 | 18 | 140 | 103 |

| 1100-0245 | 25 | 18 | 140 | 103 |

| 1100-0254 | 25 | 18 | 140 | 103 |

| 1100-0255 | 25 | 18 | 140 | 103 |

| 1100-0256 | 25 | 18 | 140 | 103 |

| 1100-0257 | 25 | 18 | 140 | 103 |

| 1100-0258 | 25 | 18 | 140 | 103 |

| 1100-0259 | 25 | 18 | 140 | 103 |

| 1100-0260 | 25 | 18 | 140 | 103 |

| 1100-0261 | 25 | 18 | 140 | 103 |

| 1100-0262 | 25 | 18 | 140 | 103 |

| 1100-0266 | 25 | 18 | 140 | 103 |

| 1100-0267 | 25 | 18 | 140 | 103 |

| 1100-0268 | 25 | 18 | 140 | 103 |

| 1100-0269 | 25 | 18 | 140 | 103 |

| 1100-0270 | 25 | 18 | 140 | 103 |

| 1100-0275 | 25 | 18 | 140 | 103 |

| 1100-0276 | 25 | 18 | 140 | 103 |

| 1100-0277 | 25 | 18 | 140 | 103 |

| 1100-0278 | 25 | 18 | 140 | 103 |

| 1100-0279 | 25 | 18 | 140 | 103 |

| 1100-0281 | 25 | 18 | 140 | 103 |

| 1100-0282 | 25 | 18 | 140 | 103 |

| 1100-0284 | 25 | 18 | 140 | 103 |

| # PULLEY | 6mm SCREW (PART #8)1 N∙m | 6mm SCREW (PART #8)1 Lbf∙po | NUT (PART #16)1 N∙m | NUT (PART #16)1 Lbf∙ft |

|---|---|---|---|---|

| 1100-0285 | 25 | 18 | 140 | 103 |

| 1100-0286 | 25 | 18 | 140 | 103 |

| 1100-0287 | 25 | 18 | 140 | 103 |

| 1100-0289 | 25 | 18 | 140 | 103 |

| 1100-0290 | 25 | 18 | 140 | 103 |

| 1100-0291 | 25 | 18 | 140 | 103 |

| 1100-0294 | 25 | 18 | 140 | 103 |

| 1100-0295 | 25 | 18 | 140 | 103 |

| 1100-0301 | 25 | 18 | 140 | 103 |

| 1100-0302 | 25 | 18 | 140 | 103 |

| 1100-0308 | 25 | 18 | 140 | 103 |

| 1100-0309 | 25 | 18 | 140 | 103 |

| 1100-0310 | 25 | 18 | 140 | 103 |

| 1100-0311 | 25 | 18 | 140 | 103 |

| 1100-0312 | 25 | 18 | 140 | 103 |

| 1100-0313 | 25 | 18 | 140 | 103 |

| 1100-0314 | 25 | 18 | 140 | 103 |

| 1100-0315 | 25 | 18 | 140 | 103 |

| 1100-0316 | 25 | 18 | 140 | 103 |

| 1100-0318 | 25 | 18 | 140 | 103 |

| 1100-0320 | 25 | 18 | 140 | 103 |

| 1100-0321 | 25 | 18 | 140 | 103 |

| 1100-0322 | 25 | 18 | 140 | 103 |

| 1100-0323 | 25 | 18 | 140 | 103 |

| 1100-0331 | 25 | 18 | 140 | 103 |

| 1100-0332 | 25 | 18 | 140 | 103 |

| 1100-0333 | 25 | 18 | 140 | 103 |

| 1100-0336 | 25 | 18 | 140 | 103 |

| 1100-0347 | 25 | 18 | 140 | 103 |

| 1100-0349 | 25 | 18 | 140 | 103 |

| 1100-0352 | 25 | 18 | 140 | 103 |

| 1100-0354 | 25 | 18 | 140 | 103 |

| 1100-0356 | 25 | 18 | 140 | 103 |

| 1100-0357 | 25 | 18 | 140 | 103 |

| 1100-0358 | 25 | 18 | 140 | 103 |

| 1100-0359 | 25 | 18 | 140 | 103 |

| 1100-0361 | 25 | 18 | 140 | 103 |

| 1100-0362 | 25 | 18 | 140 | 103 |

| 1100-0365 | 25 | 18 | 140 | 103 |

| 1100-0366 | 25 | 18 | 140 | 103 |

| 1100-0367 | 25 | 18 | 140 | 103 |

1 : See « Drive Pulley Disassembly » to correctly identify the referenced part.

NECESSARY SPECIALIZED TOOLS

web version coming soon. Please refer to the installation Manual.

1600-xxxx (Guides coming soon)

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 1600-XXXX

Download the full PDF version (coming soon)

DRIVE PULLEY DISASSEMBLY

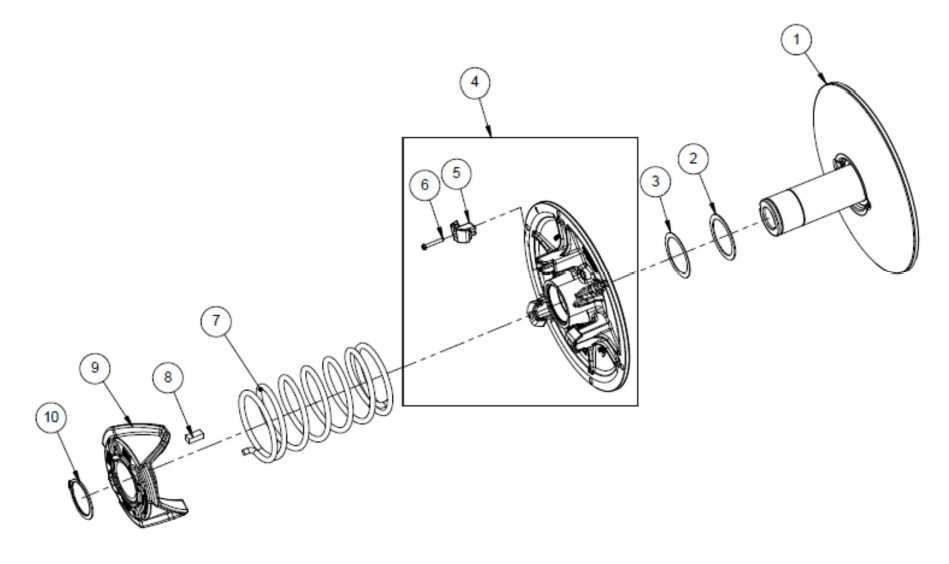

ⓘ✋

The sliding sheave ⑨ is spring loaded. When unscrewing the nut ⑮, the spring ⑦ will push the cap ⑬ and sliding sheave ⑨ up.

| # | Description | QTY |

|---|---|---|

| 1 | Fixed sheave | |

| 2 | Freewheel | |

| 3 | Spring Seat | |

| 4 | Spring seat (if applicable) | |

| 5 | Shim | |

| 6 | Stroke limiter | |

| 7 | spring | |

| 8 | Shim (If applicable) | |

| 9 | Sliding Sheave |

| # | Description | QTY |

|---|---|---|

| 10 | Centrifugal Mass | |

| 11 | Block | |

| 12 | Mass | |

| 13 | Cap | |

| 14 | Shoe | |

| 15 | Nut | |

| 16 | Fan or Ring | |

| 17 | Screw |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

| Cap shoes | Visual inspection | Replacement recommended |

Tightening Torque

web version coming soon.

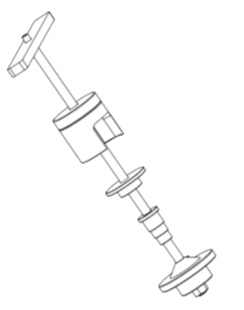

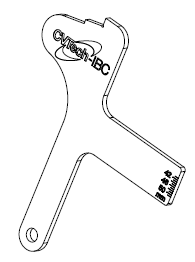

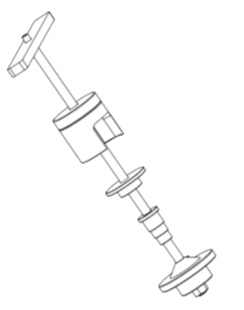

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

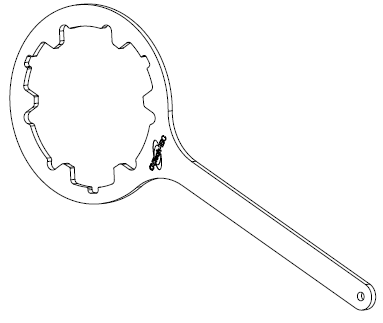

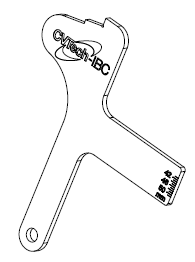

Description

Image

CVTech-IBC Number

Retaining Tool

1655-1001*

Puller

Refer to owner’s manual for part number*

* Tools available from authorized CVTech-IBC distributors

1800-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVER PULLEY 1800-XXXX

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km or 250h | Every 10000km or 500h |

|---|---|---|

| Drive pulley | Visual inspection | Disassemble and clean |

| Fixed sheave | Visual inspection | Clean |

| Sliding sheave | Visual inspection | Clean |

| Assembly of centrifugal weights | Visual inspection | Replacement recommended |

Tightening Torque

Coming soon

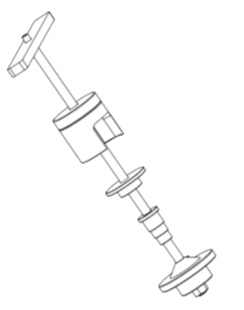

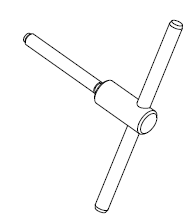

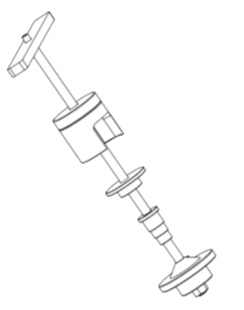

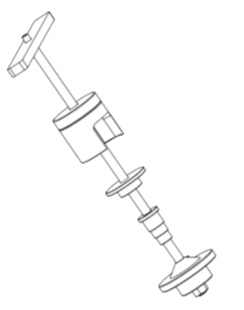

Necessary Specialized tools

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Retaining Tool

0155-1018*

Puller

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

* Tools available from authorized CVTech-IBC distributors

DRIVEN PULLEY

5600-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 5600-XXXX

Download the full PDF version (En)

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Cam | Visual inspection | Clean |

| Cam shoes | Dimension / Visual | Replacement recommended |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

5900-xxxx (Guides coming soon)

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 5900-XXXX

Download the full PDF version (coming soon)

specific instructions – 5900-0004 for ARGO vehicles since 2022 (bilingual)

Driven PULLEY DISASSEMBLY

Coming Soon

MAINTENANCE FREQUENCY

Coming Soon

Tightening Torque

Coming Soon

Outillage spécialisé requis

À VENIR

6000-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6000-XXXX

Download the full PDF version (En)

Driven PULLEY DISASSEMBLY

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Cam | Visual inspection | Clean |

| Cam shoes | Dimension / Visual | Replacement recommended |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

6100-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6100-XXXX

Download the full PDF version (En)

Driven PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | Fixed Sheave | 1 |

| 2 | Washer (If applicable) | 1 |

| 3 | Sliding Sheave | 1 |

| 4 | Cam Shoe | 3 |

| 5 | Cam Shoe Screw | 3 |

| # | Description | QTY |

|---|---|---|

| 6 | Spring | 1 |

| 7 | Key | 1 |

| 8 | Cam | 1 |

| 9 | External Retaining Ring | 1 |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Cam | Visual inspection | Clean |

| Cam shoes | Dimension / Visual | Replacement recommended |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

6300-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6300-XXXX

Download the full PDF version (En)

Driven PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | Fixed Sheave | |

| 2 | Sliding Sheave | |

| 3 | Roller | |

| 4 | Washer | |

| 5 | External Retaining Ring | |

| 6 | Spring | |

| 7 | Spring Seat |

| # | Description | QTY |

|---|---|---|

| 8 | Spring Abutment | |

| 9 | Snap Ring | |

| 10 | Forward Ramp | |

| 11 | Rear Ramp | |

| 12 | Screw | |

| 13 | Washer (If applicable) | |

| 14 | Screw (IF applicable) |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Roller | Dimension / Visual | Dimension / Visual |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

6400-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6400-XXXX

Download the full PDF version (En)

Driven PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | Fixed Sheave | |

| 2 | Washer (IF applicable) | |

| 3 | Sliding Sheave | |

| 4 | Spring Pin | |

| 5 | Roller | |

| 6 | Roller Pin | |

| 7 | Spring | |

| 8 | Spring Seat |

| # | Description | QTY |

|---|---|---|

| 9 | External Retaining Ring | |

| 10 | Forward Ramp | |

| 11 | Helix | |

| 12 | Washer (If applicable) | |

| 13 | Screw | |

| 14 | Washer (If applicable) | |

| 15 | Screw (If applicable) |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Roller | Dimension / Visual | Dimension / Visual |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

6600-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6600-XXXX

Download the full PDF version (EN)

Driven PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | Shaft Assembly | 1 |

| 2 | Fixed Sheave | 1 |

| 3 | Sliding Shoe | 3 |

| 4 | Sliding Sheave | 1 |

| 5 | Cam Shoe | 3 |

| # | Description | QTY |

|---|---|---|

| 6 | Cam Shoe Screw | 3 |

| 7 | Spring | 1 |

| 8 | Key | 1 |

| 9 | Cam | 1 |

| 10 | External Retaining Ring | 1 |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Cam | Visual inspection | Clean |

| Cam shoes | Dimension / Visual | Replacement recommended |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

6655-0002*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors

6900-xxxx

INSTALLATION AND MAINTENANCE GUIDE FOR A CONTINUOUSLY VARIABLE DRIVEN PULLEY 6900-XXXX

Download the full PDF version (En)

Driven PULLEY DISASSEMBLY

| # | Description | QTY |

|---|---|---|

| 1 | Fixed Sheave | |

| 2 | Sliding Sheave | |

| 3 | Roller | |

| 4 | Washer | |

| 5 | External Retaining Ring | |

| 6 | Spring | |

| 7 | Spring Seat |

| # | Description | QTY |

|---|---|---|

| 8 | External Retaining Ring | |

| 9 | Forward Ramp | |

| 10 | Helix | |

| 11 | Screw | |

| 12 | Washer (If applicable) | |

| 13 | Screw (If applicable) |

MAINTENANCE FREQUENCY

✋

This continuously variable pulley does not require any lubrication. It is designed to work without any lubricant. Given this, certain rules of cleanliness must be applied when handling the system to avoid having any lubricants come into contact with its components.

✋

To increase the life of the continuously variable pulley, it is strongly recommended that you respect the following recommendations:

‐ Perform maintenance according to the table below.

‐ Replace the worn parts. This ensures correct operation and will prevent any warranty from being excluded from the continuously variable pulley.

| Description | Every 5000km Or 250h | Every 10000km Or 500h |

|---|---|---|

| Driven Pulley | Visual inspection | Disassemble and Clean |

| Fixed Sheave | Visual inspection | Clean |

| Sliding Sheave | Visual inspection | Clean |

| Roller | Dimension / Visual | Dimension / Visual |

| Drive Belt | Dimension / Visual | Dimension / Visual |

Tightening Torque

Coming Soon

NECESSARY SPECIALIZED TOOLS

✋

IMPORTANT: Using impact tools is not recommended.

Description

Image

CVTech-IBC NUMBER

Flange spreader

Refer to owner’s manual for part number*

Pulley disassembly tool

5055-0002*

Alignment tool

Refer to owner’s manual for part number*

*Tools available from authorized CVTech-IBC distributors